Special Attention to Anti-slip Stability of Anti-seepage Structures in the Construction Process of Composite Geomembrane Anti-slip Stability betwe

Views :

Update time : 2024-12-12

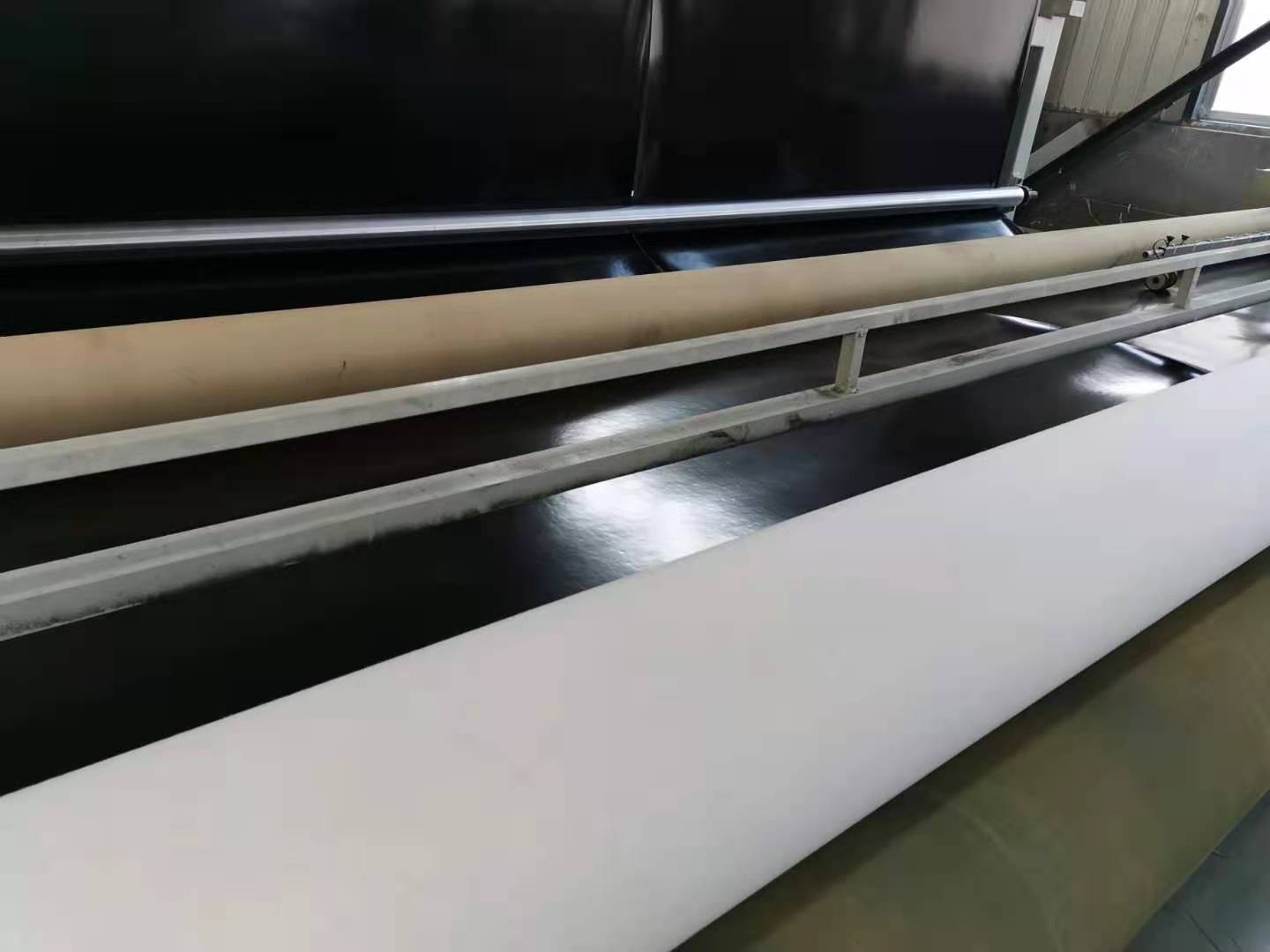

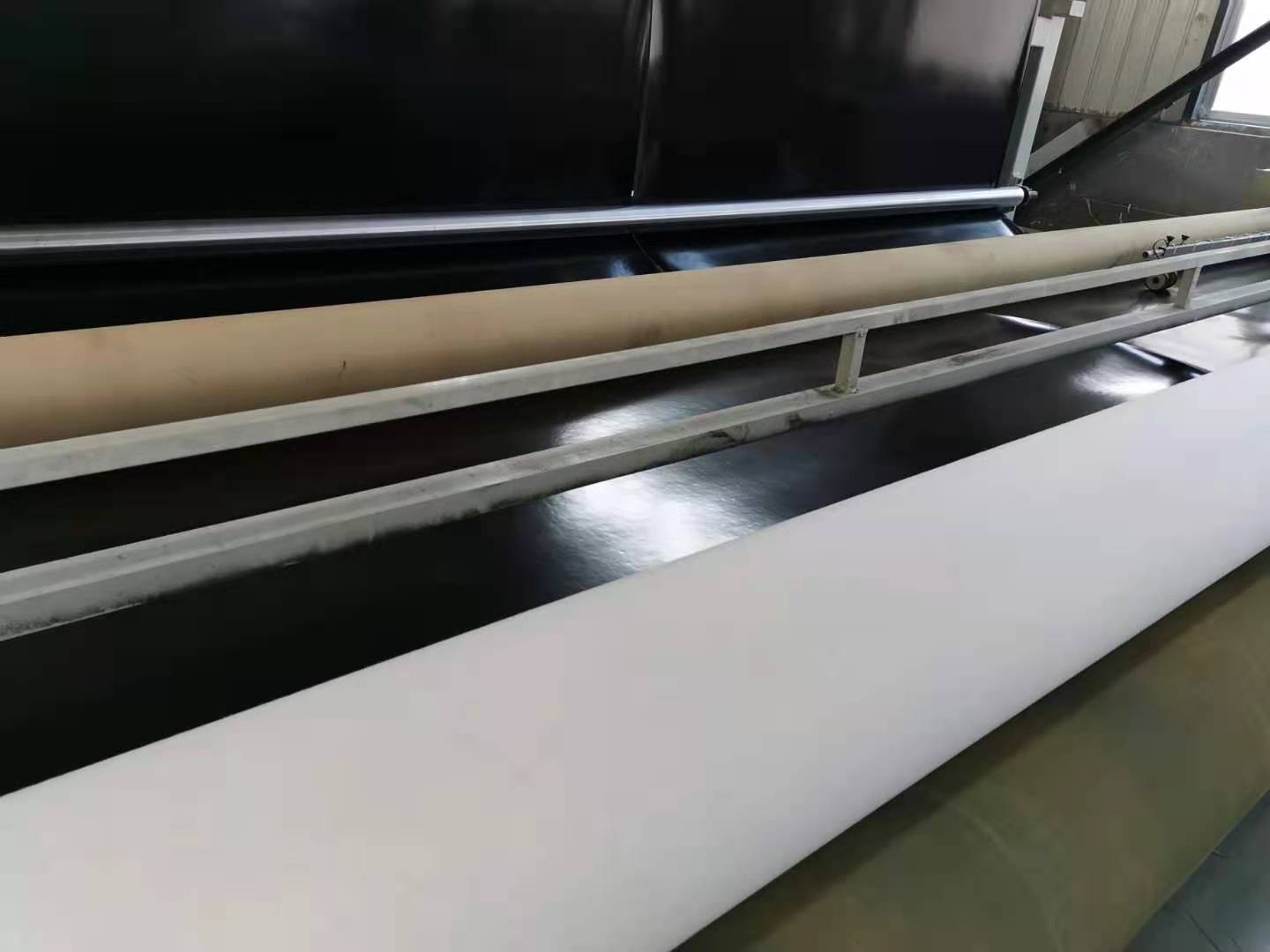

Anti-slip Stability between Composite Geomembrane and Related Layers

Under the action of the geomembrane inclined wall on the upstream dam slope, the friction coefficient between the composite geomembrane and the dam body is generally smaller than the internal friction coefficient of the dam body. Therefore, the anti-slip stability between the composite geomembrane and the protective layer, as well as between the geomembrane and the support layer or the dam body, needs to be calculated and checked. Under the action of the upstream water pressure, a relatively large anti-slip resistance is formed between the composite geomembrane and the support layer behind the membrane. Under normal anti-slip conditions, there is basically no problem with the anti-slip stability behind the membrane.

Importance of Composite Geomembrane in Environmental Protection

Stability Analysis of Anti-seepage Structures

Related News

Read More >>

What Are the Main Functions of

What Are the Main Functions of

12 .18.2024

As introduced by a leading manufacturer in Shandong, anti-seepage geomembranes s

Why Geomembranes Are Gaining A

Why Geomembranes Are Gaining A

12 .12.2024

Geomembranes, as a new type of eco-friendly material, have become highly sought-

How to Repair Damaged Composit

How to Repair Damaged Composit

12 .12.2024

IntroductionComposite geomembrane is widely used in projects such as river anti-

Special Attention to Anti-slip

Special Attention to Anti-slip

12 .12.2024

Anti-slip Stability between Composite Geomembrane and Related LayersUnder the ac