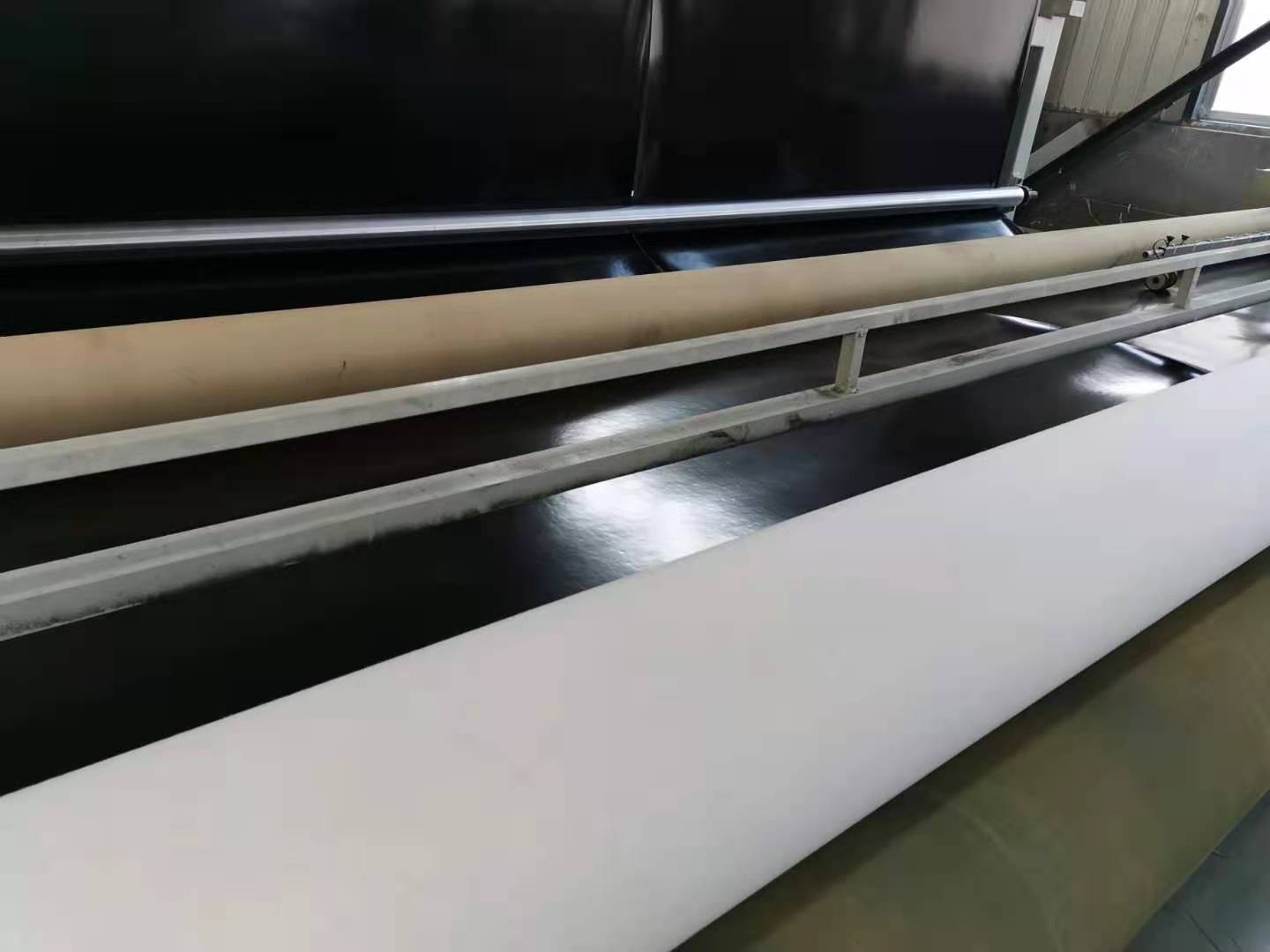

Composite geomembrane is widely used in projects such as river anti-seepage and slope protection. It has both the anti-seepage function of geomembrane and the reinforcement and soil fixation function of geotextile. However, as a large-area thin material, accidental damage and other situations are inevitable during the laying process. So, how to repair the damaged composite geomembrane during construction has become a concern for many people. Here, the editor of a Shandong anti-seepage geomembrane manufacturer has sorted out the repair methods for damaged composite geomembrane for your reference.

For the repair of damaged composite geomembrane, it is necessary to start from the cloth or membrane close to the base surface and conduct the repair layer by layer. And the repair methods for the cloth and the membrane are slightly different.

If the damaged area of the membrane is very small, special adhesive stickers can be used to repair the damaged area. The edge of the adhesive sticker should be more than 10 centimeters, and then cover and press it. If the damaged area exceeds 10 centimeters, the hole should be trimmed neatly, and a membrane slightly larger than the hole should be cut and covered on it. The edge should be firmly pasted with single-sided tape, and then compacted with feet. Alternatively, a membrane of the same size can be welded at the damaged part with a hot air gun. The welding should be firm, and the edge of the membrane should extend at least 10 centimeters beyond the edge of the hole.

When the composite geomembrane is punctured by sharp objects like crushed stones or scratched by some tools and torn, it needs to be patched and sewn. The materials selected for patching and sewing should be as similar as possible to the original materials used. The patching materials used should be about three times the size of the damaged part to ensure the quality of the patching. If the damage occurs at the interface of the composite geomembrane, the interface needs to be re-sewn and patched. The effect of sewing should be checked carefully. If there are situations like skipped stitches, it needs to be re-sewn.

If the composite geomembrane is not properly protected during storage or movement, resulting in a long crack, and the length of the crack exceeds 10% of the entire roll of material, there is no need to repair the crack. Instead, the damaged part should be directly cut off, and the remaining parts should be re-bonded.

What Are the Main Functions of

What Are the Main Functions of

Why Geomembranes Are Gaining A

Why Geomembranes Are Gaining A

How to Repair Damaged Composit

How to Repair Damaged Composit

Special Attention to Anti-slip

Special Attention to Anti-slip