Why Geomembranes Are Gaining Attention?

Geomembranes, as a new type of eco-friendly material, have become highly sought-after due to their exceptional performance and versatility in various applications. These materials play a vital role in environmental protection, water resource management, agriculture, and infrastructure projects. With the rising global demand, manufacturers in China, especially in Shandong, are increasingly expanding their production and exports, meeting the needs of international markets.

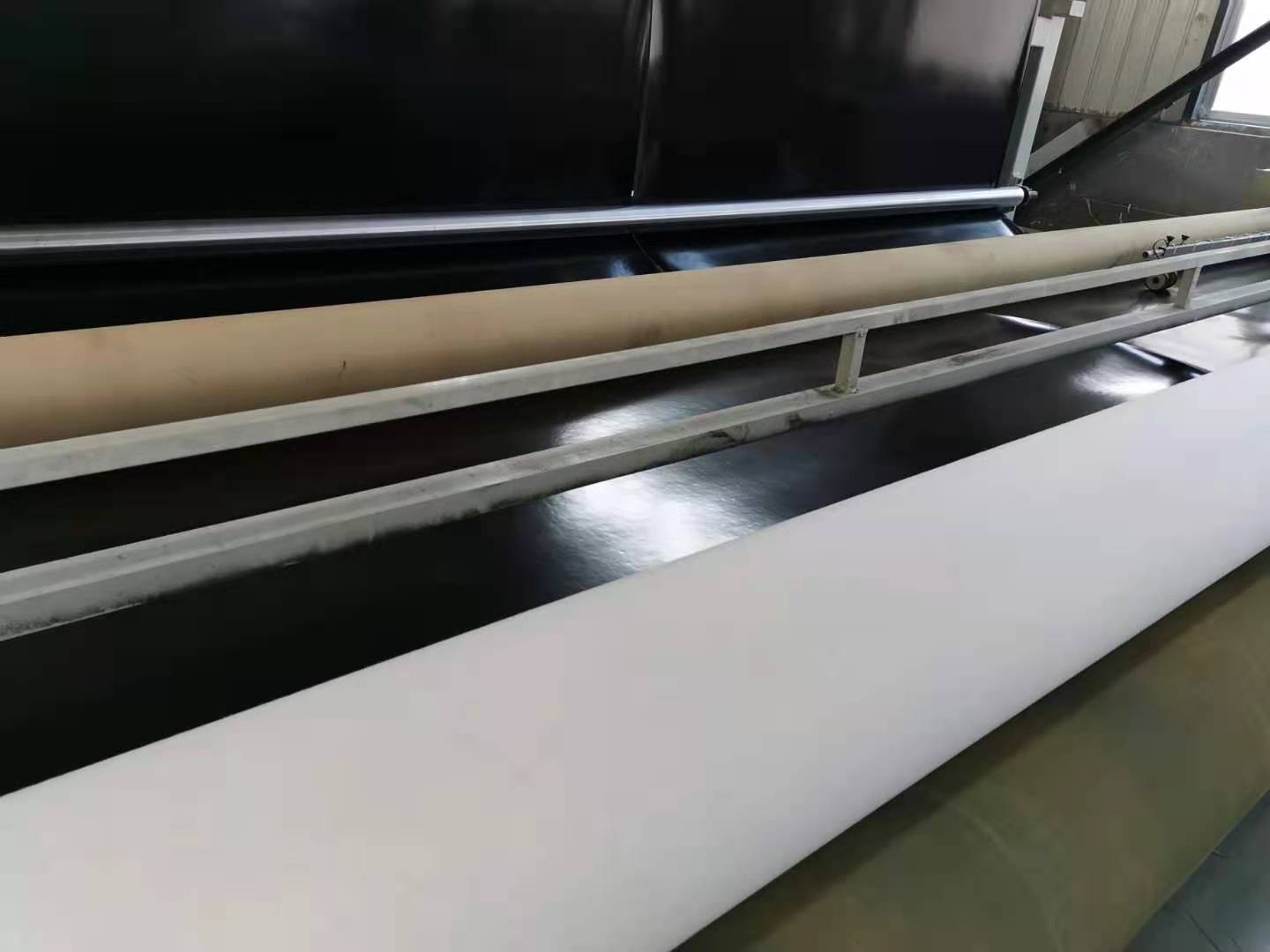

Key Features of Geomembranes

Superior Material Properties

Geomembranes are manufactured using high-density polyethylene (HDPE) or low-density polyethylene (LDPE) resins. These materials serve as impermeable barriers, excelling in flexibility, impermeability, elongation, and abrasion resistance. They also possess the following characteristics:- High Composite Strength: Ensures durability in various environments.

- Strong Peeling Strength: Resists delamination under stress.

- High Puncture Resistance: Prevents damage during installation or operation.

- Excellent Drainage Performance: Effectively channels water in engineering applications.

Low Thermal Expansion Coefficient: Minimizes deformation under temperature variations.

Multifunctionality

Geomembranes combine impermeable and drainage functionalities with structural reinforcement capabilities. They enhance soil stabilization and vibration resistance, making them indispensable in complex engineering projects.Diverse Application Scenarios

Geomembranes are widely used in:- Coastal Construction: For flood prevention and shoreline reinforcement.

- Reservoirs and Dams: To ensure water containment and prevent leakage.

- Road and Rail Projects: As a barrier against seepage and soil erosion.

- Tunnels and Underground Projects: Providing waterproofing in subterranean constructions.

- Airports and Seaports: For runway stabilization and environmental containment.

Global Demand and Market Development

The increasing demand for geomembranes in international markets has driven manufacturers to enhance production capacity and export-oriented strategies. Shandong, a leading production hub, is home to a large number of geomembrane manufacturers focused on providing high-quality products to meet global standards. These companies have invested heavily in advanced manufacturing technologies to produce geomembranes with superior tensile strength, elongation properties, and resistance to environmental stress cracking, making them ideal for international engineering projects.

However, not all geomembranes are created equal. Buyers should evaluate suppliers based on their production processes, quality certifications (such as ISO and CE standards), and past export performance. Establishing long-term partnerships with reputable suppliers ensures consistent quality and reliable delivery schedules.

Installation and Quality Assurance

Proper installation is critical to the performance and longevity of geomembranes. International standards, such as ASTM and GRI, outline stringent requirements for material selection, welding techniques, and installation protocols. Skilled technicians and quality control measures are essential during deployment to avoid damage and ensure seamless integration into the project.

Key installation considerations include:

- Avoiding sharp objects or rough surfaces that may puncture the geomembrane.

- Employing precision welding techniques to create impermeable seams.

- Conducting post-installation inspections to verify structural integrity.

A well-installed geomembrane can significantly extend its service life, providing robust protection and cost efficiency for decades.

Advantages for Export Markets

Geomembranes are increasingly recognized as essential materials in modern infrastructure and environmental projects. Their benefits for international buyers include:

- Eco-Friendly Construction: Meets global sustainability goals.

- Customizable Solutions: Tailored thickness, textures, and sizes for specific applications.

- Cost Efficiency: Competitive pricing due to advanced production techniques in China.

- Proven Durability: Long service life ensures minimal replacement costs.

Partnering with Trusted Geomembrane Suppliers

As a leading exporter of geomembranes, Chinese manufacturers have established themselves as reliable partners for global engineering projects. With certifications, robust logistics networks, and a commitment to quality, Chinese geomembranes are well-positioned to meet the growing international demand.

For export inquiries or further information on geomembrane solutions, contact trusted suppliers who can deliver high-quality products tailored to your project needs.

What Are the Main Functions of

What Are the Main Functions of

Why Geomembranes Are Gaining A

Why Geomembranes Are Gaining A

How to Repair Damaged Composit

How to Repair Damaged Composit

Special Attention to Anti-slip

Special Attention to Anti-slip